2/0 AWG Lugs for Battery, Grounding, and Power Distribution Systems

In the world of high-current electrical systems, the integrity of your connection is just as important as the gauge of your wire. When dealing with heavy-duty applications like commercial battery banks, solar power inverters, or industrial grounding, 2/0 AWG lugs (often referred to as 2/0 gauge lugs) are the gold standard for ensuring safety and efficiency.

Choosing the right lug isn’t just about finding a piece of metal that fits; it’s about managing heat, preventing corrosion, and ensuring maximum conductivity over the lifespan of the system.

Understanding 2/0 AWG Specifications

To appreciate the role of 2/0 gauge lugs, one must first understand the “00” (Double Aught) wire size. A 2/0 AWG copper conductor has a diameter of approximately 0.3648 inches (9.27 mm) and is designed to carry significant amperage—typically up to 175–195 Amps depending on the insulation temperature rating and environment.

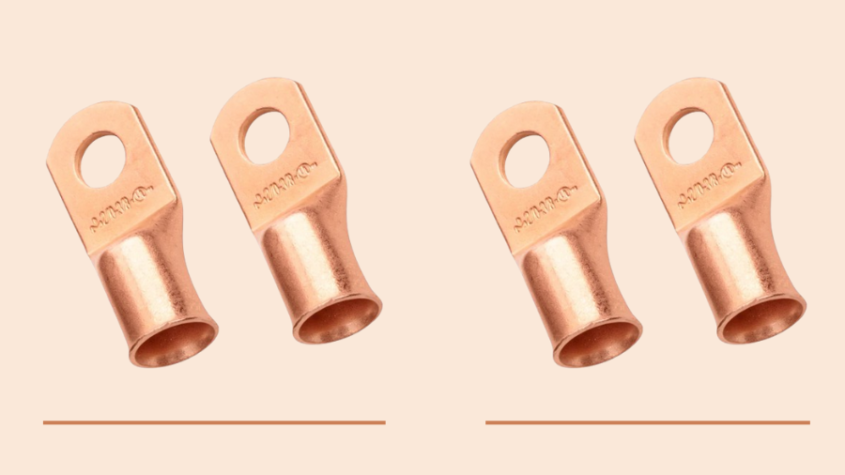

Because these cables handle such high power, the terminal connectors must be robust. 2/0 AWG lugs are heavy-duty tube terminals designed to be crimped or soldered onto the end of the cable, providing a flat, stable surface (the “palm” or “tongue”) to bolt onto a battery terminal, busbar, or chassis.

Key Applications for 2/0 Gauge Lugs

Battery Bank Interconnects

In off-grid solar arrays or Marine/RV power systems, batteries are often wired in series or parallel to achieve the desired voltage and capacity. Using high-quality 2/0 gauge lugs ensures that there is minimal voltage drop between cells. A loose or poor-quality connection at the battery post can lead to localized heating, which can melt battery terminals or, in extreme cases, cause a fire.

Grounding Systems

Safety grounding requires a path of least resistance to the earth or the vehicle chassis. In industrial settings, a 2/0 AWG lug is frequently used to bond equipment to a grounding busbar. Because grounding wires often sit idle until a fault occurs, these lugs must be highly resistant to oxidation so they can perform instantly when called upon to shunt thousands of amps of fault current.

Power Distribution and Inverters

Large DC-to-AC inverters (3000W and above) pull massive amounts of current from a 12V or 24V source. To feed these “hungry” devices, thick 2/0 cabling is required. The 2/0 AWG lugs used here must be flared at the entry point to allow for easy insertion of high-strand-count “welding cable,” which is often preferred for its flexibility in tight distribution panels.

Material and Construction: Why It Matters

Not all lugs are created equal. When sourcing 2/0 gauge lugs, there are three critical factors to consider:

Pure Copper vs. Brass

Always opt for lugs manufactured from 100% seamless electrical grade copper (ASTM B-152). Copper offers the highest conductivity. Some cheaper alternatives use brass, which is harder and more prone to cracking under the pressure of a crimping tool, and it possesses significantly lower conductivity.

Tin Plating

Bare copper is beautiful but vulnerable. In automotive or marine environments, copper oxidizes quickly, forming a layer of “green crust” (verdigris) that adds resistance. High-quality 2/0 AWG lugs are electro-tin plated. This plating acts as a barrier against corrosion while maintaining excellent electrical contact.

Closed-End Design

For battery and outdoor applications, “closed-end” or “sealed-end” lugs are superior. This design ensures that the end of the cable is completely encased in copper, preventing moisture and oxygen from wicking up into the wire strands, which can lead to internal cable decay.

Proper Installation: Crimping vs. Soldering

The debate between crimping and soldering is long-standing, but in the modern industry, mechanical crimping is the preferred method for 2/0 gauge lugs.

- The Cold Weld: A proper hydraulic crimp creates a “cold weld” between the lug and the wire. This means the copper of the wire and the copper of the lug are compressed so tightly that air is eliminated, creating a single solid mass of metal.

- The Solder Risk: Soldering such a large gauge (2/0) requires immense heat, which can damage the wire insulation. Furthermore, solder can “wick” up the wire, making it brittle and prone to cracking under vibration—a major concern in vehicle or boat applications.

Steps for a Perfect Connection:

- Strip the Wire: Remove just enough insulation so the conductor fits fully into the barrel of the 2/0 AWG lug without leaving exposed copper.

- Select the Die: Use a dedicated 2/0 or 70mm² die in a hydraulic crimper.

- Crimp: Apply pressure until the die faces meet. For 2/0 gauge, two crimps (one near the palm, one near the wire entry) are often recommended.

- Heat Shrink: Always finish the connection with adhesive-lined heat shrink tubing. This provides strain relief and seals the connection against the elements.

Safety Standards and Certifications

When purchasing 2/0 gauge lugs, look for UL Listed or CSA certified products. These certifications ensure the lugs have been tested to withstand specific pull-out forces and heat cycles. In a power distribution system, a sub-standard lug is the weakest link; investing in UL-listed 2/0 AWG lugs provides peace of mind that the connector can handle its rated load indefinitely.

Conclusion

Whether you are building a backup power system for a data center or wiring a winch on an off-road vehicle, the humble 2/0 AWG lug is the anchor of your electrical system. By choosing tin-plated, seamless copper lugs and utilizing a proper hydraulic crimp, you ensure that your power distribution is efficient, cool-running, and built to last for decades.

High-current systems leave no room for error. By prioritizing quality in your 2/0 gauge lugs, you are not just making a connection—you are protecting your equipment and ensuring the safety of everyone who relies on it.

Easy tips and tricks to clean your sofa at home

The sofa is the center of your living space. Your sofa is a place where you can relax, ent…